LAST UPDATED: May 1st, 2015

Ask 10 bowhunters which broadhead they prefer for slaying whitetails and you’re likely to get 10 different answers. And each guy will swear the one he uses is the only one to buy. “I’m telling you man, you don’t want to shoot anything other than the” – (insert a broadhead name here). The simple fact is, there’s probably at least one bowhunter out there who will swear by each broadhead on the market. If there wasn’t, that head would disappear from said market. The question you have to answer before deer season opens is, “Which one’s right for me?”

Ultimately, the right broadhead is the one that flies true, cuts a big nasty hole, leaves a wicked blood trail to follow, and kills deer as quickly as possible. Find a broadhead that performs like that, and you’ll be one of those guys that swears by your choice.

LIKE BULLETS?……NOT

Step one in the quest to finding your broadhead soul mate is to understand the purpose of a broadhead. That might seem like a no-brainer, but every year guys climb into their stands with arrows bearing heads that have dull and/or chipped blades. And if you understand the broadhead’s purpose, that’s the last thing you would ever do.

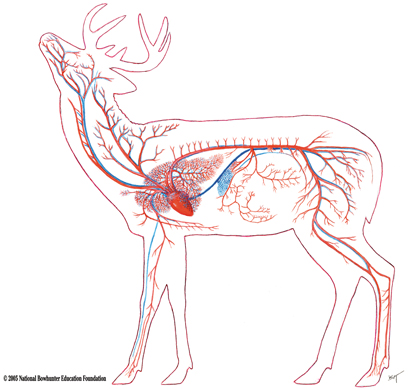

Bullets kill by shock, and by causing massive tissue and organ damage. You can hit a deer square in the shoulder with a bullet, and it will be dead before it hits the ground. Shock killed that deer before it had a chance to bleed. Arrows, on the other hand, kill solely by causing hemorrhage – bleeding. They don’t hit with enough force to kill by shock. To get the kind of blood loss necessary to kill a whitetail, your arrow has to slice into vital organs or through critical arteries that supply the body with blood.

Unlike bullets, broadheads must kill by causing extreme blood loss. This means blades must be razor-sharp to increase performance and must ultimately slice vital organs and arteries.

Keep in mind, the arrow doesn’t actually do any cutting. It’s simply the delivery system for the broadhead. That’s where the magic happens. And if the head is dull, it’s not going to have near the potential killing capacity of one with razor-sharp blades. Think about running a butter knife over your finger versus a scalpel. Which one’s going to cause more damage? No matter what head you choose, remember this – the sharper the better. I have yet to hear one bowhunter complain, “Man, such-and-such broadheads are just too dang sharp.”

GENERALIZATIONS

Most broadheads on the market today are made of stainless steel. Others are carbon-steel or titanium. The carbon-steel and titanium heads are certainly more durable than the stainless heads, but they can cost considerably more. If money is no object, go for the higher-end heads. If cash is something you have to consider, pick a stainless head. Trust me plenty of deer have been killed with stainless-steel broadheads.

The right choice in broadheads will make the blood trail short and the memories last a lifetime.

To keep headaches to a minimum, pick a broadhead that weighs the same as your field points – 100 grains, 125 grains, etc. Ideally, the broadhead should fly just like your field points. This means you won’t have to adjust your sights before hunting with them. However, nothing is guaranteed, so be sure to spend some time on the range with your broadheads to determine if any sight changes are necessary.

Essentially, broadheads can be divided into two basic categories – fixed blade and mechanical. Mechanical-type heads are those that have moving parts, while fixed blade broadheads, as their name suggests, have none.

FIXED-BLADE

We’ll start our discussion with fixed blades, since they are the granddaddy of all broadheads. They’ve been around since the first human affixed a piece of flint to the end of an arrow with sinew and pine pitch.

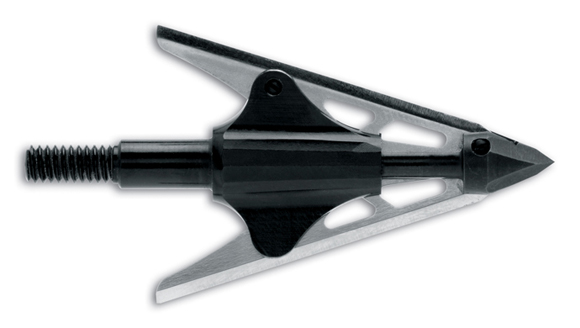

With fixed blades, you’ve got anywhere from two to four razors protruding from a head shaft that cut on contact. That is, they start cutting the instant they hit a deer. These heads are simple and they have no moving parts to cause problems. And, a lot of them are sturdy enough that you can reuse them after killing a deer simply by re-sharpening the blades.

Fixed-Blade heads are proven to be deadly killers when used correctly and shot from a properly setup bow rig. Pictured here is the NAP Thunderhead Razor.

Because the blades on a fixed-blade head are solidly planted in place, these heads generally are considered the best for penetration. In some cases, you can hit a bone and the head will plow right through. By comparison, the blades on mechanicals tend to be more flimsy because they are not attached to the ferrule at the base.

Because of their design, with the blades perpetually protruding from the ferrule, fixed-blade heads have been known to sail off course during flight. Essentially, the blades can act as rudders, catching a bit of air, and take the arrow away from your aiming point. You’re not going to miss by a couple feet, mind you, but at 40 or 50 yards, your dead-nuts heart shot can turn into a gut shot very fast.

Understand that fixed-blade heads are not designed to sail. In a perfect world, they will fly just like your field tips, because that’s what the manufacturers had in mind when they created them. But we don’t live in a perfect world and sometimes bowhunters shooting fixed-blade heads occasionally have “fliers” – arrows that inexplicably sail off the intended aiming point. So it’s something to consider.

Properly squaring the end of the arrow shaft, as well as the insert, will ensure that the broadhead ferrule sits flush against the arrow; therefore reducing the risk of “fliers”.

Often times, fliers are caused by an improperly cut arrow shaft. If the shaft is not cut perfectly straight, then the ferrule that sits inside the shaft is going to list to one side. This will ultimately cause your broadhead to do the same once it is screwed onto the ferrule. That broadhead will surely steer your arrow off course when air hits blades. If you have a problem with fixed-blade fliers, take your arrows to an archery pro shop, and have an expert check to make sure the sailing isn’t related to an uneven shaft cut.

The bigger the blades are, the more prone a head is to sailing. That’s why most fixed-blade heads sport cutting diameters of less than 2 inches. Maintaining accuracy with blades sticking out that far from the head of the shaft is tough to do unless everything is perfect. And, while a foxed-blade head with 1.5-inches of cutting diameter is plenty big enough to get the job done, one of the bonuses of mechanical heads is that you can have cutting diameters of up to 2.5 inches with little worry about the aforementioned problems.

MECHANICALS

Shoot enough arrows, with a large assortment of heads attached to the end and you’ll soon discover that there is no head that allows for truer arrow flight than the simple, bullet-shaped field point. And that only stands to reason, since it’s perfectly aerodynamic. Mechanical broadheads are designed to imitate that bullet-shaped design as closely as possible while in flight, yet still provide a cutting surface upon impact.

Some mechanicals have two or three blades that fold up entirely against the shaft of the head, so virtually nothing protrudes. One such head is the NAP Scorpion. These blades then deploy, either by unfolding from the tip backwards, or by sliding out from the rear. With the blades deployed, these heads can provide cutting diameters up to 2.5 inches and will indeed leave a huge hole in whatever they hit.

The NAP Bloodrunner is a mechanical-hybrid that offers the best of both worlds; modest demensions for stable flight, and a massive cutting diameter upon impact.

Other mechanicals have blades that protrude modestly in flight, but then slide out farther on impact to expand the cutting diameter. Take the NAP Bloodrunner 2-Blade, for example. Its cutting diameter is 1 1/8-inches in flight, but stretches to 2 1/16-inches on contact.

Periodic “fliers” are typically not a problem bowhunters experience when using mechanical heads. In fact, many manufacturers of mechanical heads advertise them with slogans, such as, “Flies just like a field point.” As a result, consistent accuracy is a main selling point of mechanical broadheads.

DOWNSIDES

When it comes to what a mechanical broadhead “can’t” do, as mentioned, the blades on a lot of mechanical heads are flimsy. Hit a bone the wrong way, and the blades will fold. A folded blade isn’t much good for cutting vital arteries and/or organs.

Also, and this is one of the leading complaints bowhunters have with mechanicals, the blades sometimes don’t deploy correctly. This is a problem most commonly associated with heads where the blades fold out from front to back, as opposed to the rear-deploying models, which came into existence, quite frankly, in response to problems with blades not folding out from the front. If the blades on a fold-up mechanical don’t deploy on contact, you’re essentially shooting a deer with a field tipped arrow.

The NAP Killzone is a vastly improved version of the highly popular “rear-deploying” mechanical. It offers devestating cutting diameters and is guaranteed to open upon impact and never during flight.

Another point to consider is that with most mechanical broadheads, you’re looking at one-shot use. The blades just don’t maintain enough straightness after they’ve hit a deer or the ground to use them again. Some mechanicals have replaceable blades, which is less expensive then replacing the whole head. If you shoot a lot of deer each season, you might want to invest in mechanical heads with replaceable blades to get more for your money. Some guys have also had problems with mechanicals that deploy “in flight”, long before contact. You don’t have to be an aeronautical engineer to understand how that can adversely affect accuracy.

Remember, these problems are not universal. Mechanical heads are designed so that the blades deploy perfectly only on contact. And for many bowhunters, that’s the only way their heads have ever operated. But occasional problems with blades that deploy early or not at all do exist, so you need to be aware of those before making a decision about which broadhead will accompany you into the timber.

[PAGE:5]

IMPROVED DESIGNS

Early on, all mechanical heads basically looked the same. Each had blades that folded up completely from the back toward the tip, and deployed in reverse upon contact. Mechanical heads like the NAP Bloodrunner 2-Blade were invented in order to provide at least some cutting surface in the event the blades don’t function properly. If you shoot a Bloodrunner into a whitetail or any other animal and the blades don’t work, you’ve still got 1 1/8 inches of cutting diameter slicing through hide, flesh, and vital organs.

If you want to see more of these, take the time to test-shoot your broadheads before opening day.

CONCLUSION

If you’re trying to decide which broadhead is best for your particular setup and the game you intent to hunt, the best advice is to test, test, test…..and test some more. Try different models on the range and in the woods until you find one that works the way you want it to. When you reach that point, you will have found your broadhead “soul mate”….and the next game animal standing downrange will be in dire trouble.

By

By